Portland Composite Cement

Product Description

Product Name : LANWA Sanstha Portland Composite Cement

Designation : Portland Composite Cement

Strength Class: 42.5N

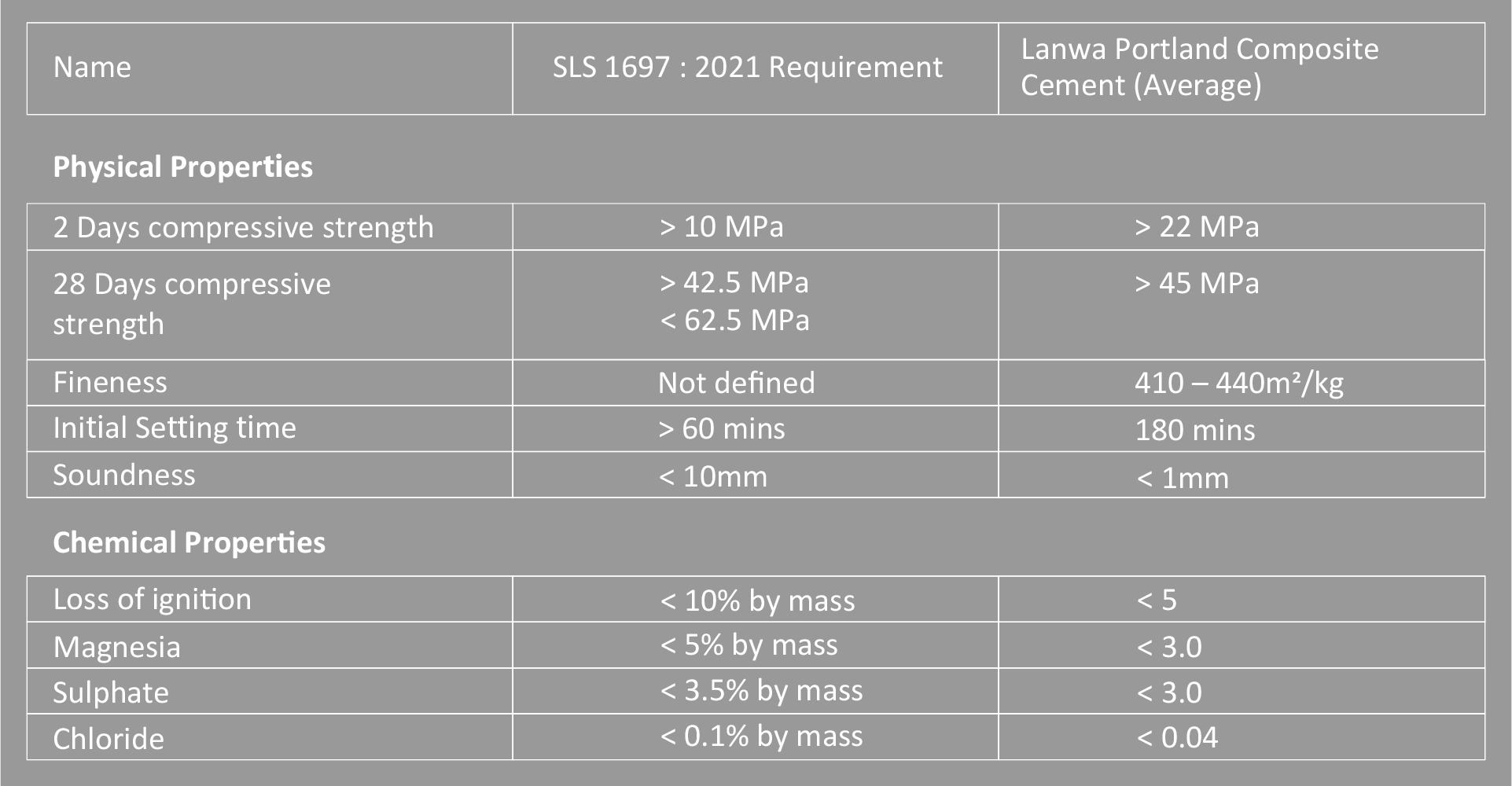

Comply With : SLS 1697:2021

LANWA Sanstha Portland composite Cement is a quality-assured cement, manufactured in compliance with SLS 1697:2021 product specification, the national standard. The cement is produced using high-quality raw materials followed by strict quality control procedures focusing on the high consistency final product to exceed the customer’s satisfaction.

product features

Better Concrete Performance

LANWA PCC is developed by a finely ground combination of clinker, slag/fly ash, and CaCO3. Fine particles in the LANWA PCC increase concrete workability and reduce the possibility of uncontrolled bleeding in concrete. The reaction of Slag / Fly ash would make the concrete much denser while increasing its strength and providing further protection for the steel reinforcement of the concrete. Finely ground CaCO3 particles fill the small cavities in the concrete, reducing porosity and the permeability of water and other reactive chemicals.

Better Precast Products

LANWA PCC is engineered to deliver more strength in a shorter time, which supports the achievement of high strength at an early age of the concrete. Compared to conventional cement, this helps precast concrete producers in reducing the time necessary for formwork removal. Furthermore, LANWA PCC would enable the fabrication of lean precast segments at competitive prices by supporting the use of high-strength concrete mixes with lower cement contents.

Improved Crack Resistance

The engineered minerals in LANWA PCC would increase the concrete’s resistance to fresh and hardened stage cracking. Ground slag particles in the LANWA PCC would improve the bleeding rate in concrete and protect it against cracking caused due to severe desiccation. Furthermore, the slag in it will extend the period allotted for concrete surface finishing. Concrete produced with LANWA PCC will resist corrosion ion penetration and assist in preventing corrosion of the reinforcing steel. As a result, the frequency of reinforcement steel corrosion-related cracks will decrease.

Smooth Finishes

LANWA PCC is produced by introducing finely ground CaCO3 into the cement. Finely ground CaCO3 particles would reduce the friction among the ingredients in concrete and deliver superior workability during finishing works. Further, Tiny CaCO3 particles within the cement.

Compatibility

- Concrete admixtures complying with BS EN 934-1:2008 or equivalent

- Manufactured sand (M-Sand), Sea sand, Recycled aggregate, and natural sand

- Mixing with supplementary Cementitious material

Technical Compliance