Blended Hydraulic Cement

Product Description

Product Name : LANWA Sanstha Blended Hydraulic Cement

Designation : Portland Slag Cement

Strength Class: 42.5N

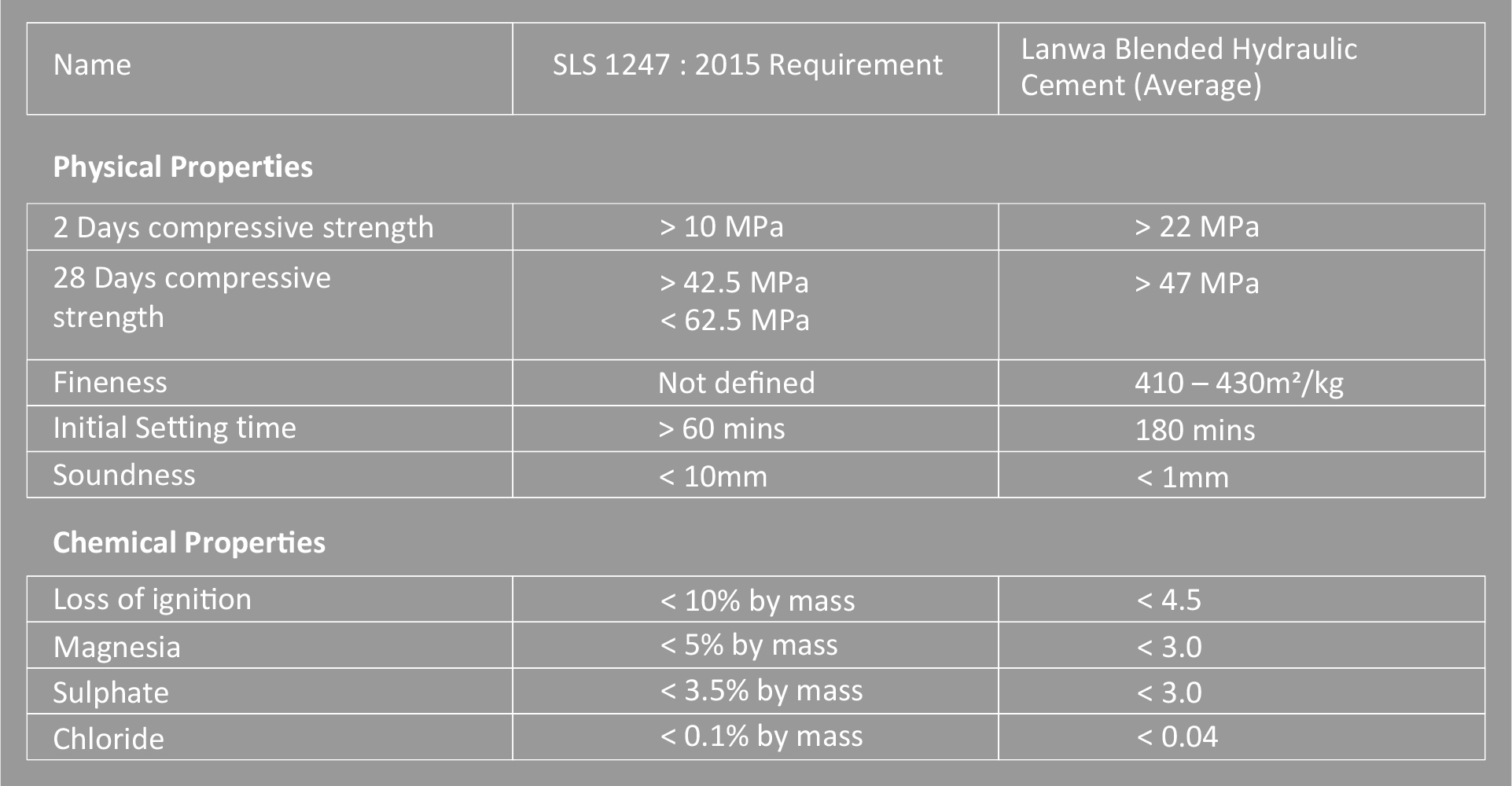

Comply With : SLS 1247:2015

LANWA Sanstha Portland Slag Cement is a quality-assured cement, manufactured in compliance with SLS 1247:2015 product specification, the national standard. The cement is produced using high-quality raw materials followed by strict quality control procedures focusing on the high consistency final product to exceed the customer’s satisfaction.

product features

Exceptional Concrete Performance.

LANWA BHC is the best choice for producing concrete with exceptionally fresh and hardened properties. The subdued water consistency and extended setting time of LANWA BHC assure superior workability of concrete mixes. Furthermore, it guarantees the enhancement of the performance of concrete in the face of raw material scarcity. The fineness and proportion of slag in LANWA BHC are chosen to provide the highest concrete strengths, making it an ideal solution for developing high-performance concrete mixes.

Hostile Environment Conditions

LANWA BHC would be an ideal preference for increased concrete protection in adverse environmental conditions. By preventing the reaction and permeability of chloride ions, the slag reaction of LANWA BHC ensures the highest resistance to chloride attacks. Therefore, concrete structures made with LANWA BHC will prolong last in hostile environments without regular maintenance.

Mass Concrete Applications

Encouraging mass concreting applications, LANWA BHC expands the faster and more efficient construction opportunities for reinforced concrete structures. The risk of reducing the concrete durability due to delayed ettringite formation (DEF) and thermal cracking can easily be controlled by using LANWA BHC. As a result, LANWA BHC might use to enhance the volume of concrete used in a single pouring, which decreases construction costs.

Best Concrete Economy

The lowered retarding chemical agent requirement of LANWA BHC allows you to produce time-extended concrete mixes at a lower cost. Further, LANWA BHC can be mixed with additional quantities of GBFS/FA to develop the concrete properties and increase the likelihood of large concrete pouring.

Compatibility

- Concrete admixtures complying with BS EN 934-1:2008 or equivalent

- Manufactured sand (M-Sand), Sea sand, Recycled aggregate, and natural sand

- Mixing with supplementary Cementitious material

Technical Compliance